Operating Elements¶

Please refer to the corresponding page for the ROX: Operating Elements.

Depending on the application and the cobot arm installed, an EMROX can have various additional operating elements. If available, please check the customised documentation for your individual robot, which you may find in the customer area of our website. The following elements are present in many EMROX projects.

Cobot Main Switch¶

Most cobot arms have their own main switch and are not directly linked to the activation of the mobile platform. This means that the ROX base platform must be switched on first and then the robot arm. When switching off, the robot arm should always be shut down properly and switched off before switching off the base platform.

Note

Whenever possible, please first shut down the robot arm properly using the function provided for this purpose before switching off the base platform. Otherwise, the arm controller or the configuration files of the arm may be damaged.

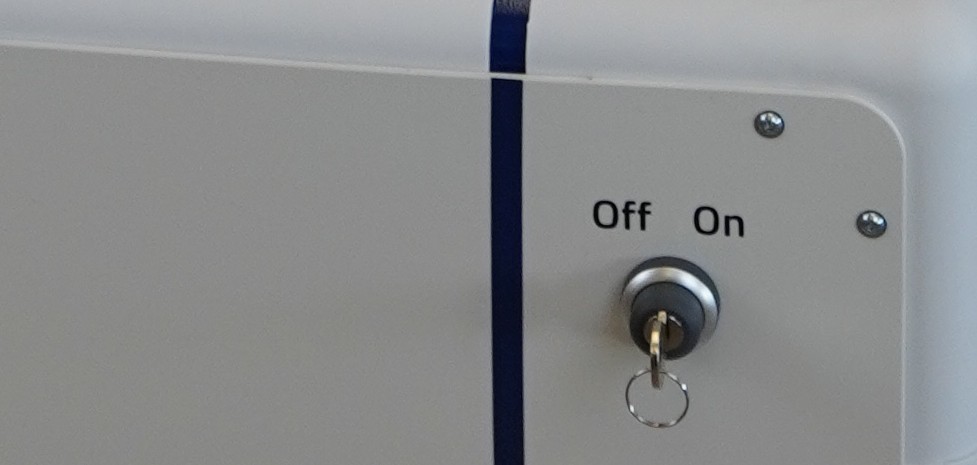

The EMROX housing has an additional main switch for robot arms whose hand-held control unit is removed during automatic operation. This is usually designed as a push-button rotary switch. Turn it briefly to the right to switch on the robot arm and to the left to switch it off.

Operating Mode Switch¶

In some applications, it may be useful to be able to manually select between different operating modes. This is particularly necessary in situations where one or more safety functions need to be deactivated, such as when temporarily operating without the radio emergency stop. Activation of these operating modes purely by the sequence controller software is not permitted, as otherwise there is a risk of incorrect switching and thus a dangerous state.

Enabling Switch¶

In certain situations, it may be necessary to use an enabling button in addition to an operating mode selector switch. This is the case, for example, if the regular protective functions used in automatic mode cannot be used, but on the other hand, simply deactivating them, even briefly, would lead to an unacceptable risk. In this case, the only solution is to use an enabling button in monitored mode, in which the operator can immediately trigger an emergency stop if problems are detected.

Indicator Lights¶

For longer, continuous operation of the robot arm at one position, it may make sense to use an additional indicator light only for the status and actions of the arm and possibly even to deactivate the lights of the base platform for this time. This makes it easier for personnel to differentiate between the various operating states and minimises the risk of sensory overload or dulled attention. Overall, this can improve both operational safety and the well-being of employees.

Please contact us if you require application-specific modifications to the EMROX indicator lights.

DC Power Switch¶

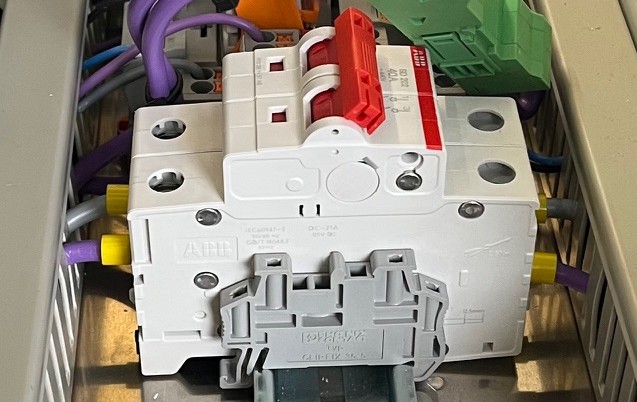

If a cobot arm supplied with DC voltage is installed, it is usually permanently connected to the batteries of the mobile robot and this connection is maintained even when the robot is switched off. Depending on the robot arm, this can lead to two potential problems.

- If the arm constantly consumes energy even when switched off, for example through standby functions, this can drain the batteries if the mobile robot is inactive for a very long time.

- Even after disconnecting the batteries from the mobile robot, electrical energy may initially still be stored in the capacitors and the arm’s electrical system, which represents a potential source of danger during electrical works.

For this reason, every EMROX with a DC-supplied arm is equipped with a two-pole disconnector in the body. This can be used to manually disconnect the arm from the robot’s power supply if required.

Tip

On an EMROX with LiFePO4 batteries, the batteries can also be conveniently switched off externally using the LFP activation switch. The entire robot is then de-energised even when the DC disconnector is closed and the batteries cannot be excessively discharged.

Reset After Emergency Stop¶

Both the mobile platform and the cobot arm have their own safety controllers and should generally be seen as separate units that are linked together. In many cases, the cobot arm also has an emergency stop button, usually on the hand-held control unit, which must be manually unlocked and reset on the cobot after being pressed. The steps for resetting mergency stops therefore vary depending on the cause.

Safety Fields¶

As with the ROX, with the EMROX, a protective field violation also only has a temporary effect as long as an obstacle is detected in the currently active protective field. As soon as the obstacle has been removed and all protective fields are clear, the safety system is automatically released again after a short waiting time. The same behaviour normally applies both when moving the mobile base and when moving the arm only. However, it is also possible to program a different behaviour in the Flexi Soft safety controller if required for the individual application.

Emergency Stop Buttons of the Platform¶

Each time an emergency stop button on the mobile platform or the EMROX superstructure is pressed, the platform’s safety controller switches to the emergency stop state. It remains in this state until the pressed button is unlocked by turning it and the error state is reset via the key switch. During this time, the robot arm cannot be moved but is only in a safe operating stop. Its safety system does not have to be reset as well but automatically returns to normal operation as soon as the emergency stop of the platform has been cleared.

Emergency Stop Buttons at the Arm or Pendant¶

When an emergency stop button is pressed on the robot arm or its hand-held pendant, it is the arm’s safety controller that switches to the full emergency stop state while the platform is only in the safe stop state. In this case, the emergency stop must therefore be reset directly on the robot arm or hand-held pendant after the button has been unlocked. The platform automatically switches to normal operation as soon as the arm is ready for use again.